Streamlined production means excellent product quality.

Today, the factory occupies an area of 1200 m² and is capable of producing up to 10,000 products per month. The production facilities are equipped with high-tech knitting, sewing and quilting equipment, advanced technologies are used, and high production standards are met at all stages. More than 35 years of experience allows us to produce knitwear of consistent and reliable quality.

The team consists of qualified specialists with many years of experience. Employees regularly upgrade their qualifications, undergo training and internships, which ensures continuous improvement of their professional skills. The models are developed by experienced technologists and designers, taking into account all the features, so each product gets a perfect fit.

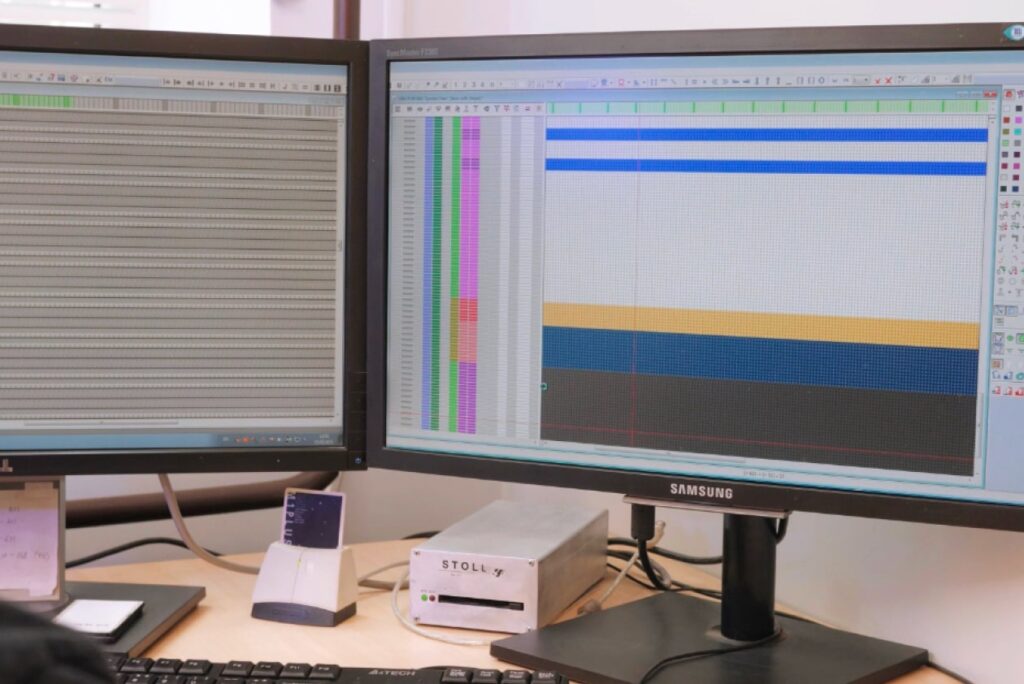

Attention to handmade work certainly does not exclude the use of technology. Every stylistic idea is realized with the help of computer graphics programs.